HEAT TREATMENT

Heat treatment involves the use of heating or chilling, normally to extreme temperatures, to achieve a desired result such as hardening or softening of a material. Heat treatment techniques include annealing, case hardening, precipitation strengthening, tempering and quenching.

RFTS is a full-service provider that has transformed Heat Treatment, by integrating emerging technology and equipment advancements to produce the industry’s most efficient heat treatment solution.

The main activities of RFTS in NDT heat treatment solutions include the post weld heat treatment on piping, vessels, components and equipment of power plants, refineries and chemical plants. Besides the classical systems with resistances and induction, RFTS performs heat treatments with heated air and pre-heats with infrared equipment. The company designs and builds resistance (high voltage and low voltage) and induction machinery for localized pre-heat treatments, burners for heat treatments using heated air, mobile furnace (Temporary Furnaces can be built to client’s specifications and are suitable for temperatures up to 1040 degrees Celsius) and temperature recorders.

RFTS is equipped with a large amount of up to date equipment and can boast of vast experience in heat treatment. We manufacture, own and operate the most technologically advanced heat treatment equipment available in the market.

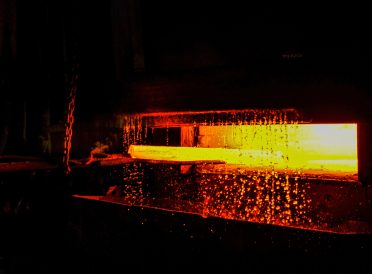

HEAT TREATMENT GALLERY

CLICK ON IMAGE TO ENLARGE